Important factors affecting mechanical intelligent manufacturing

The parts we produce include stamping, mechanical processing, sheet metal welding, mold design, extrusion molding, and other intelligent manufacturing of parts,

All cannot be separated from the five major factors: personnel, machines, materials, methods, and environmental factors.

These five elements have a significant impact on the quality of parts. The following is a detailed analysis of the impact of these five elements on part quality:

Personnel:

1. Importance: Personnel are the biggest challenge in production management and the focus of discussion in all management theories. The personality traits, skill level, and work attitude of personnel will directly affect the quality of parts.

2. Impact mode: Different personality traits can affect production progress, attitude towards work, and understanding of product quality. Therefore, as a leader, it is necessary to treat employees with different personalities differently, explore the strengths of their personality traits, weaken their weaknesses, and maximize their work efficiency.

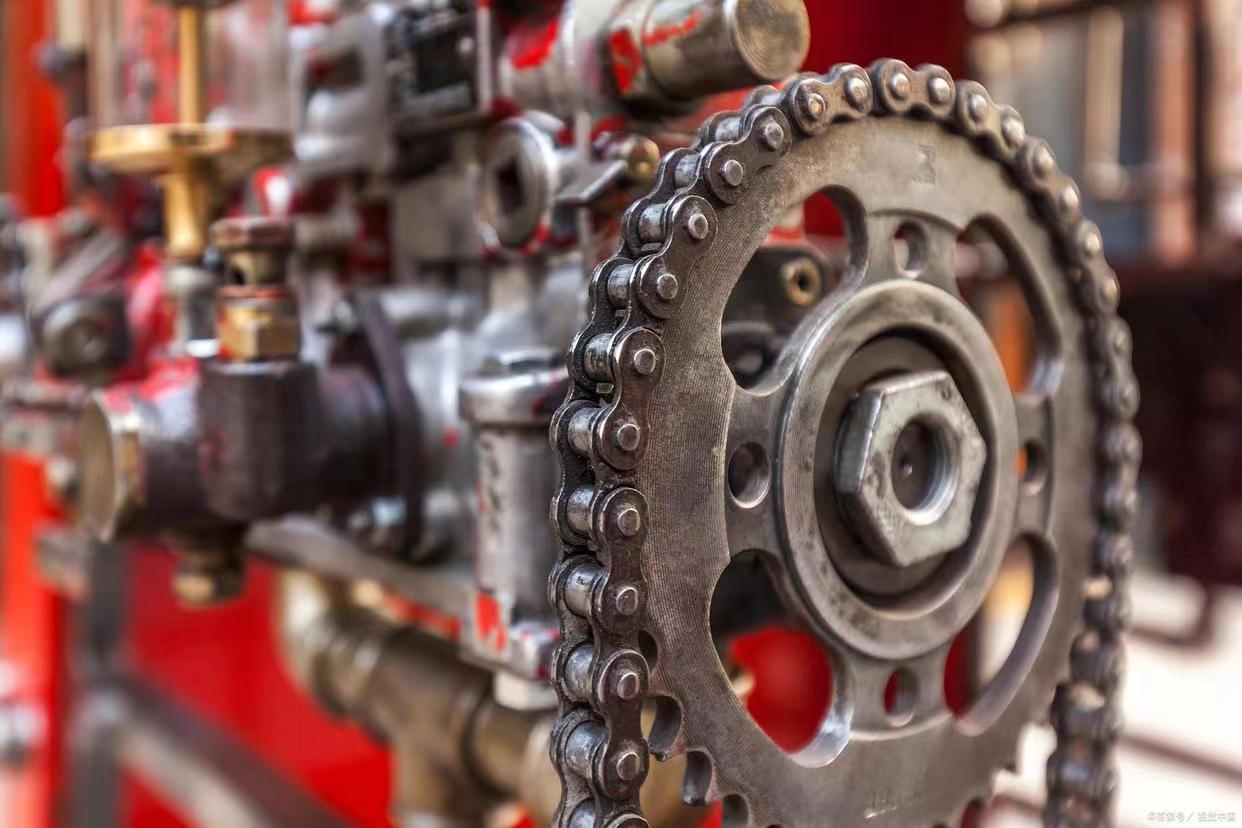

Machine:

1. Importance: Machines are important auxiliary tools in the production process, and the normal operation of equipment and the quality of tools directly affect production progress and product quality.

2. Impact mode: Good equipment can improve production efficiency, reduce errors and deviations in the production process, and thus improve product quality. For example, the transition from hand saws to machine saws not only improves efficiency, but also reduces the physical requirements for personnel.

Material:

1. Importance: Materials are the foundation of producing parts, and their quality directly affects the quality of the final product.

2. Impact mode: In industrial product production, division of labor is refined, and incomplete completion of one component may lead to the inability to assemble the entire product, affecting production progress. Meanwhile, unqualified materials can directly affect the performance and service life of the parts.

Law:

1. Importance: The principle refers to the methods used in manufacturing products, including process flow, operating procedures, etc. The correct methods and processes are key to ensuring product quality.

2. Impact mode: If the method is improper, it may lead to product defects or non-compliance with requirements. For example, when machining small parts on a lathe, if the relevant technology is not mastered or data is not rechecked, it may lead to product quality issues.

Environment:

1. Importance: The environment refers to the environment in which the product is manufactured, including temperature, humidity, cleanliness, etc. A good environment is the foundation for ensuring stable product quality.

2. Impact mode: Changes in environmental factors may have an impact on the production process and product quality. For example, in the welding process of aluminum alloy, if the environmental humidity is too high or the transmission of protective gas is interrupted, it may lead to the generation of defects such as pores.

In summary, personnel, machines, materials, methods, and environment are the five major factors that interact and constrain each other in the manufacturing process of parts, jointly determining the quality of the parts. These components are all permeating the aerospace, automotive, medical equipment, agricultural machinery, smart home, automation equipment, and other fields. Therefore, in order to ensure stable and reliable product quality, comprehensive management and control need to be carried out from these five elements.