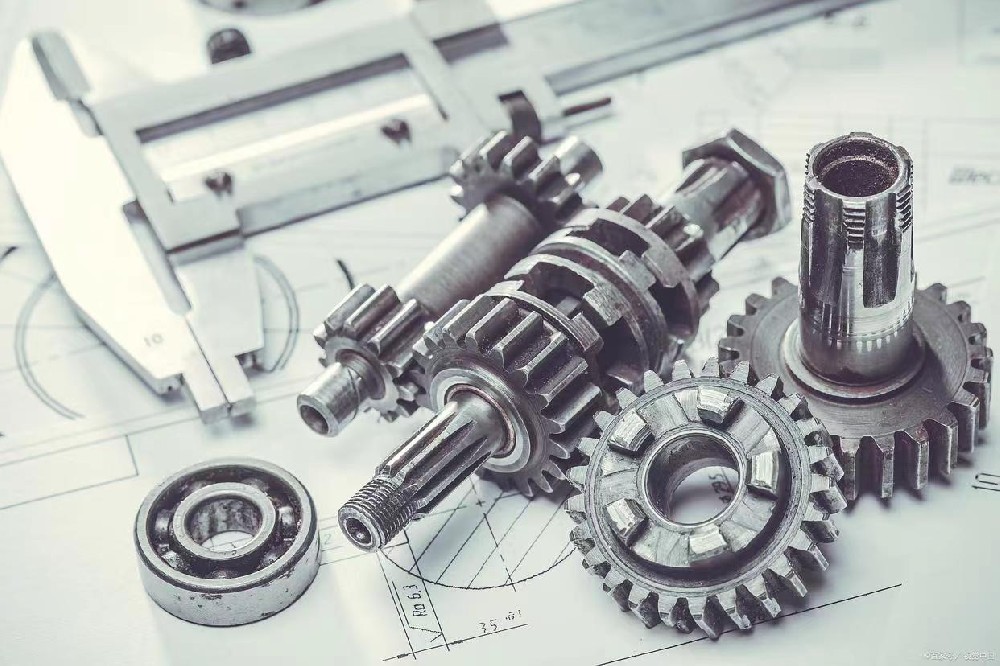

The effect of parts on the whole equipment

The parts we produce need to be designed, including mold design, welding processing, stamping, CNC machining, and other production industries, which need to meet the assembly and use requirements of the entire equipment, so

Parts play a crucial role in the entire equipment, its role is mainly reflected in the following aspects:

1. The basic unit of the equipment: parts are the most basic unit of the equipment. Whether it is a complex industrial equipment or a simple daily item, it is composed of multiple parts in accordance with certain structural and functional requirements. The type, quantity, material and accuracy of these parts directly affect the performance and function of the equipment.

2. To achieve the functions of the equipment: the various functions of the equipment are realized through its parts. For example, in mechanical equipment, the transmission part is responsible for transmitting power and torque, the actuator is responsible for completing a specific action or operation, and the control part is responsible for adjusting and controlling the operating state of the entire equipment. These components work together to enable the equipment to complete a variety of complex tasks according to predetermined requirements.

3. Affect the performance of the equipment: the performance and quality of the components directly determine the performance of the entire equipment. High-quality components can ensure the stability, reliability and safety of the equipment, and improve the service life and efficiency of the equipment. On the contrary, if there are quality problems or insufficient performance of parts, it will lead to equipment failure, reduce production efficiency and even cause safety accidents.

4. Easy maintenance and upgrade of the equipment:

since the equipment is composed of multiple parts, when the equipment fails or needs to be upgraded, it can be achieved by replacing or improving the relevant parts. This modular design makes the maintenance and upgrading of equipment more convenient and fast, reducing maintenance costs and time.

5. Reflect the technical level and value of the equipment:

the design and manufacturing level of parts is an important sign to measure the technical level of a device. Advanced parts design and manufacturing technology can improve the performance and quality of equipment, reduce production costs, and improve market competitiveness. At the same time, high-quality parts are also one of the important manifestations of the value of equipment, which can bring higher economic benefits to enterprises.

In short, parts play a vital role in the entire equipment. They are not only the basic unit of the equipment, but also responsible for realizing the function of the equipment, affecting the performance of the equipment, facilitating the maintenance and upgrade of the equipment, and reflecting the technical level and value of the equipment. Therefore, in the design and manufacturing process of the equipment, we must attach great importance to the selection of parts, design and manufacturing quality to ensure the performance and quality of the entire equipment.